All-Composite Residential Dock Crowns New England Showpiece

Berkley, Massachusetts

Corinne and Barry McNeill’s striking dock is made almost entirely of composite materials. Spanning 125 feet into the Taunton River, the structure came together in under a year from concept to completion. Since the pilings, decking and other components will outlast their wooden counterparts by decades, the Berkley, MA couple wanted everything to be perfect. Happily, the Pearson team was on hand to help throughout the process. “Once we decided we wanted all-composite, they handled everything,” explains homeowner Barry McNeill “This is really their field of expertise.” Featuring Pearson’s exclusive Monopile design, the dock looks as good as it lasts.

Design that Speaks for Itself

Through their experience developing and designing luxury homes, the McNeills have honed their critical eye for detail and quality. So when they wanted pilings that would endure New England’s harsh environs, they knew where to turn. Pearson’s composite pilings resist rot, rust and pests so your initial investment can last generations. “When Barry first walked in, he was looking for pilings,” recalls Pearson Pilings President, Mark Pearson. But when he saw the sample of the all-composite, monopile design at their Somerset, MA manufacturing facility, Barry was intrigued. Corinne, an interior designer, shared his enthusiasm.

Timeless Style

The minimalist, industrial style appealed to their aesthetic, while the long-term cost savings matched their buy-it-for-life mentality. Unlike wooden docks, the look and finish of Pearson’s all-composite monopile dock remains constant through time, reducing maintenance costs.

When Good Sense Meets Great Taste

Partnering with marine contractor Brendan Lund of Borden Light Marine Contracting, Inc., Pearson took the McNeill’s dream dock from design, manufacture and indoor assembly over the winter to construction and installation in the fall. Since Pearson Pilings and their partners are familiar with the properties of composites and their installation requirements, everything went as planned. BLMC was able to assemble the dock sections off site and deliver completed sections to the site. After the pilings were driven the pre-assembled sections were lifted into place and bolted to the pilings. Assembly off site (not over water) and pre-drilled fastening points reduced the time on site and the overall time to build the dock.

Uniquely You

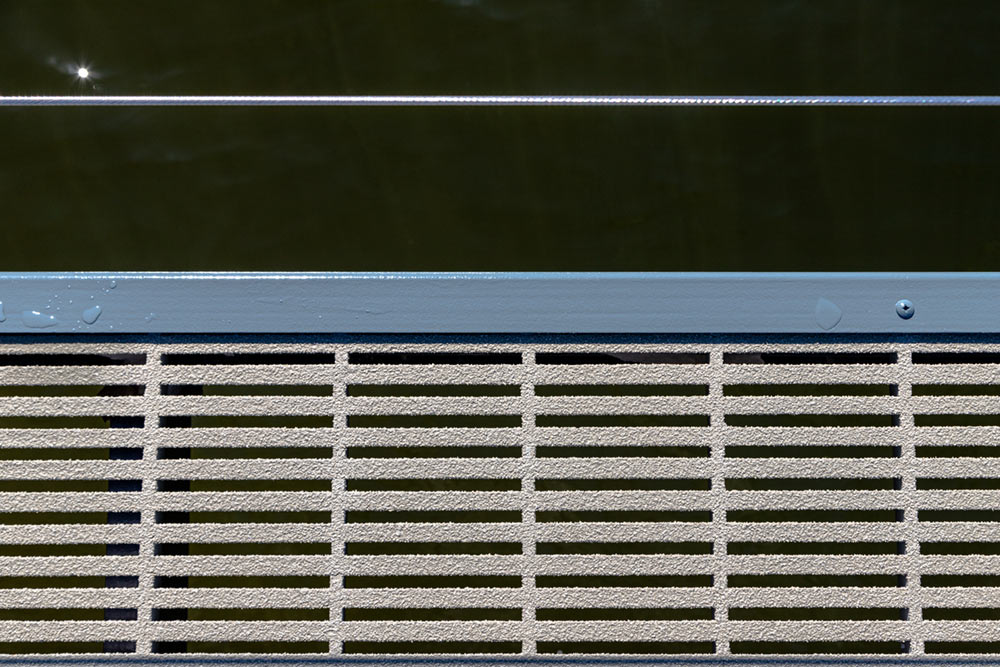

Due to the extra load that Pearson Pilings can handle, the monopile design uses fewer pilings than traditional docks. Customizable through piling color, decking color, end caps and more, the sleek design served as inspiration for the creative couple. The resulting dock has a look that’s both modern and timeless: the black pilings blend in with the dark water and contrast against the bright decking.

Dream Destination

Involved in every detail down to the feel of the decking against bare feet, Corinne and Barry created the dock to be the finishing touch on their waterfront dream home. “We knew we wanted something that would last, that looked amazing, that we could be proud of,” Corinne says. Thanks to Pearson Pilings, their dream is built to last for generations.

Additional Views

aerial view

all composite premium decking

monopile design

all-composite pilings

industrial design

We knew we wanted something that would last, that looked amazing, that we could be proud of.—Corinne McNeill, Homeowner, Berkley, MA